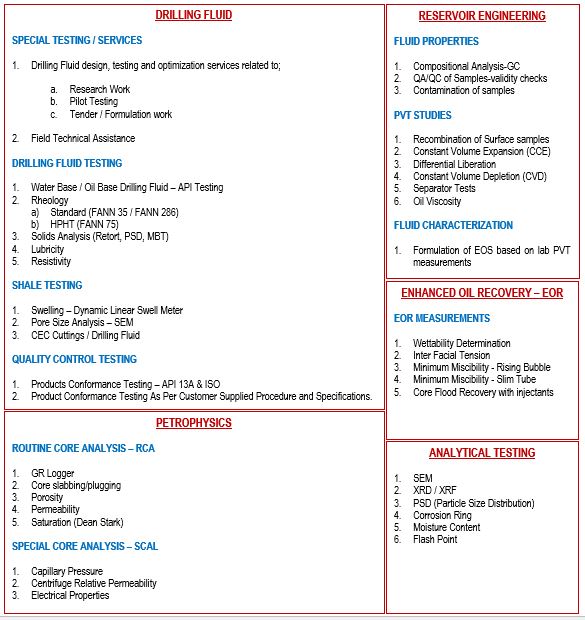

The knowledge of petroleum fluid phase behavior plays a crucial role throughout the Oil & Gas industry, from reserves estimation to reservoir production to surface processing to transportation and storage. Phase behavior modeling is vital, but often taken for granted. Whether an equation of state or a simple black-oil model is used, it needs to be specifically built and tuned to the experimental PVT data for each unique fluid. Only then can the model be used to make the necessary engineering predictions.

In physics and thermodynamics, an equation of state is a thermodynamic equation relating state variables which describe the state of matter under a given set of physical conditions, such as pressure, volume, temperature (PVT), or internal energy. Equations of state are useful in describing the properties of fluids, mixtures of fluids and solids. In a practical context, equations of state are instrumental for PVT calculations in reservoir engineering problems, such as petroleum gas/liquid equilibrium calculations. A reservoir fluid model based on a calibrated equation of state is the key to proper design, evaluation and prediction of fluid flow in hydrocarbon projects.